FBT splitters and PLC splitters are two popular types of splitters used in the telecommunication industry. While they have some similarities, such as their ability to divide signals into multiple channels, they have significant differences in terms of bandwidth, size, insertion loss, temperature sensitivity, reliability, and cost.

Here’s a table comparing PLC (Planar Lightwave Circuit) splitters with FBT (Fused Biconical Taper) splitters, focusing on several key aspects to help understand their differences and applications:

| Feature | PLC Splitter | FBT Splitter |

|---|---|---|

| Principle of Operation | Uses optical waveguide technology to split light evenly. | Uses the fusion and tapering of fibers to split light. |

| Splitting Ratio | Evenly | Different Ratios |

| Uniformity | High uniformity across all output ports. | Uniformity decreases as the number of splits increases. |

| Loss | Lower insertion loss and higher consistency. | Higher and variable insertion loss, especially in higher split ratios. |

| Polarization Dependency | Low polarization dependent loss (PDL). | Higher PDL, which can affect signal quality. |

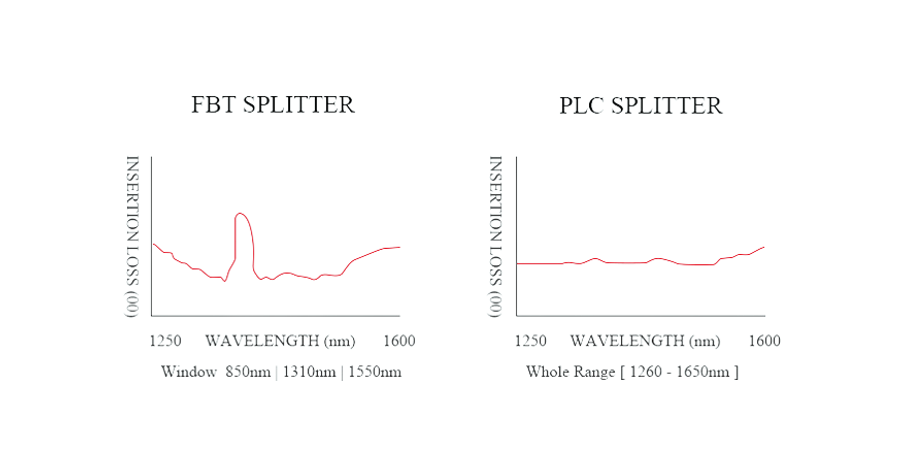

| Wavelength | 1260nm-1620nm | 850nm, 1310nm, 1490nm and 1550nm, Single or Dual |

| Size | Compact, can accommodate many splits in a small form factor. | Larger in size, especially as the number of splits increases. |

| Cost | Generally more expensive, cost increases with the number of splits. | Less expensive for low split ratios but can become cost-inefficient at higher splits. |

| Application | Ideal for large-scale and dense fiber networks like PON networks. | Suited for simpler, smaller scale applications or where budget constraints exist. |

| Reliability | High reliability due to solid state construction. | Good reliability, but can be sensitive to physical stress and environmental conditions. |

How to Choose PLC Splitter and FBT Splitter?

Both PLC and FBT splitters have their unique advantages and are chosen based on the specific requirements of the network, including the scale of deployment, cost considerations, and performance requirements. PLC splitters are favored in modern, high-density fiber optic networks due to their scalability, consistency, and compact size, while FBT splitters find use in smaller, high power applications where fewer splits are needed.

Want to Wholesale PLC Fiber Splitters for Your Project?

Start with Low MOQ Today

What is FBT Splitter? Pros and Cons

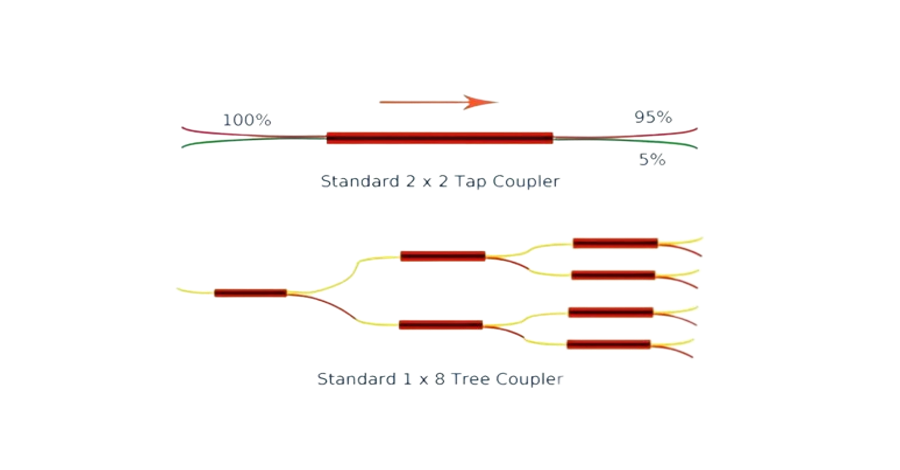

FBT (Fused Biconical Taper) splitters are one of the oldest types used in the telecommunication industry. They are made by fusing and tapering two or more fibers together, which causes the signal to split evenly across each channel. FBT splitters are typically made from silica glass fibers and are used in single-mode and multimode fiber optic systems.

FBT splitters are available in various configurations, such as 1×2, 1×4, 1×8, and 1×16, and can handle high-power signals. However, FBT splitters have limitations, such as limited bandwidth and large size.

Pros

- FBT splitters are cheaper because they are made from readily available and inexpensive materials.

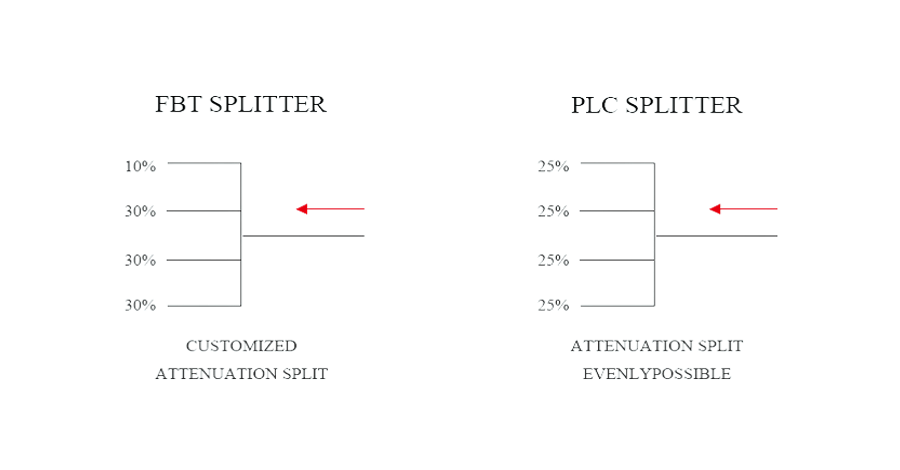

- The split ratio can be customized.

Cons

- Limited to its operating wavelengths (850nm, 1310nm and 1550nm).

- Maximum insertion loss will vary by split, especially for splits over 1:8 where it will increase significantly.

- Because the exact ratio cannot be guaranteed, it will affect the transmission distance.

- High-Temperature Dependent Loss (TDL).

- Susceptible to failure due to extreme temperatures or improper handling.

What is PLC Splitter? Pros and Cons

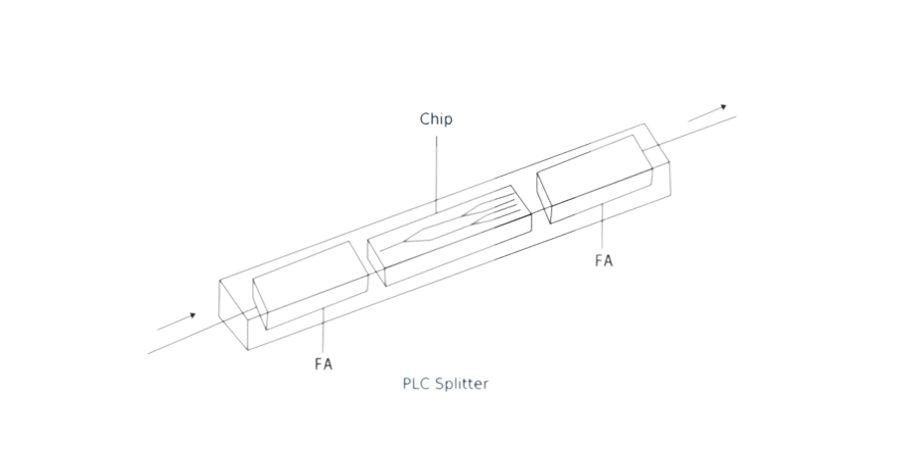

PLC (Planar Lightwave Circuit) splitters are a newer type of splitter that has gained popularity in recent years. They are made by using a silica wafer to create a waveguide circuit that divides the signal into multiple channels. PLC splitters are commonly used in single-mode fiber optic systems.

PLC splitters are available in various configurations, such as 1×2, 1×4, 1×8, and 1×16, and can handle high-power signals. They are also available in a range of split ratios, such as 50/50, 70/30, and 80/20, among others.

Pros

- Suitable for various working wavelengths (1260nm – 1650nm).

- The split ratio of all branches is equal.

- The configuration is compact, the volume is smaller, and the space occupied is small.

- Good stability in all ratios.

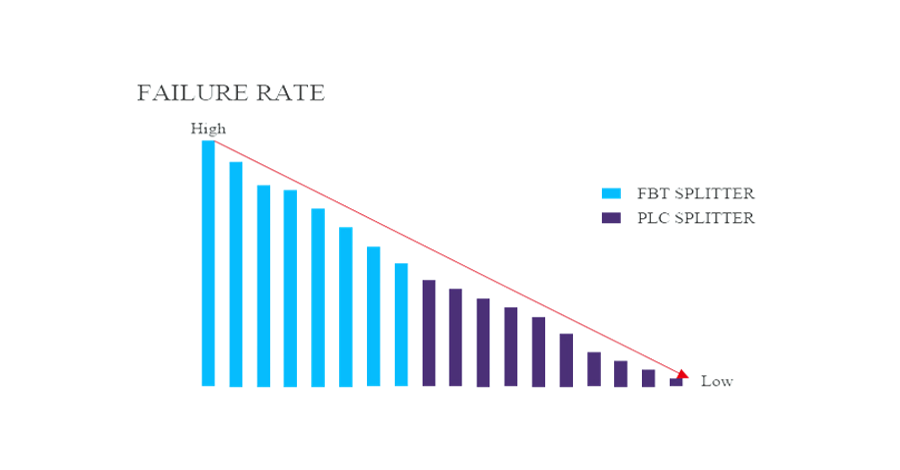

- High quality, low failure rate.

Cons

- The production process is complicated.

- More expensive than FBT separators at smaller ratios.

Customize PLC Fiber Splitters

Good Quality, Low MoQ

What are the Differences?

Working Wavelength

The FBT splitter only supports three wavelengths: 850nm, 1310nm, and 1550nm, and cannot work at other wavelengths. PLC splitters can support wavelengths from 1260 to 1650nm. The adjustable wavelength range makes the PLC optical splitter suitable for more applications.

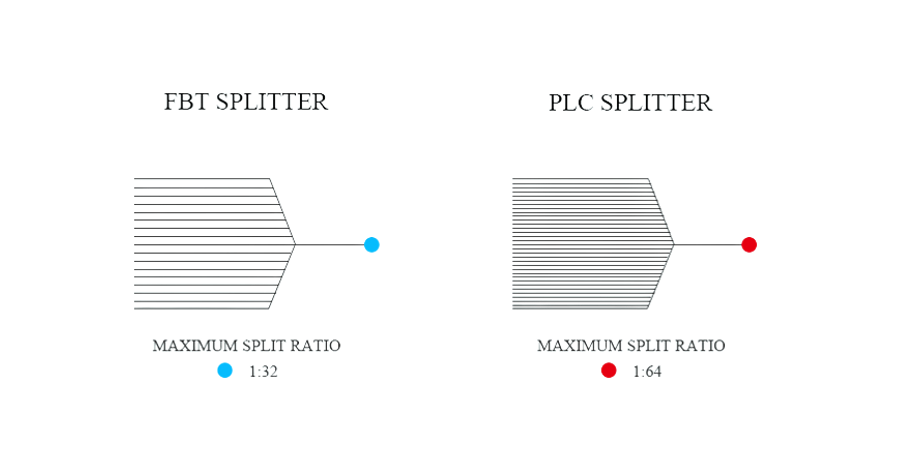

Split Ratio

The splitting ratio is determined by the input and output of the fiber optic splitter. The maximum splitting ratio of the FBT splitter is as high as 1:32, which means that one or two inputs can be split into outputs of up to 32 fibers. However, the splitting ratio of the PLC splitter is as high as 1:64—one or two inputs and the maximum output is 64 fibers. In addition, FBT splitters can be customized, and special models include 1:3, 1:7, 1:11, etc. However, PLC splitters cannot be customized, and there are only standard types such as 1:2, 1:4, and 1. :8, 1:16, 1:32, etc.

Spectral Uniformity

The signal processed by the FBT splitter cannot be evenly distributed due to the lack of signal management. And the more points, the worse the uniformity, affecting its transmission distance. The PLC splitter can support the splitting ratio of all branches to be equal, which can ensure more stable optical transmission.

Failure Rate

FBT splitters typically require a splitter configuration with a network of less than 4 taps. The larger the split, the higher the failure rate. When its split ratio is greater than 1:8, more errors will occur, resulting in a higher failure rate. Therefore, FBT splitters are more limited by the number of splits in one coupling. But the failure rate of the PLC splitter is much smaller.

Temperature Sensitivity

FBT splitters are more sensitive to temperature fluctuations than PLC splitters, and they can work stably at temperatures ranging from -5 to 75°C. This is because FBT splitters are made by fusing optical fibers together, which causes them to expand or contract when their temperature changes. PLC splitters, on the other hand, are made using silicon wafers that are less sensitive to temperature changes. It can work in a wider temperature range of -40~85°C, providing relatively good performance in extreme climate regions.

Size

PLC splitters are smaller in size than FBT splitters, making them ideal for use in applications where space is limited. They can be easily integrated into compact devices, such as routers and switches, without taking up too much space.

Cost

FBT splitters are generally less expensive than PLC splitters, making them a more cost-effective option for some applications. However, the price difference between the two types of splitters is becoming smaller as the demand for PLC splitters continues to increase.

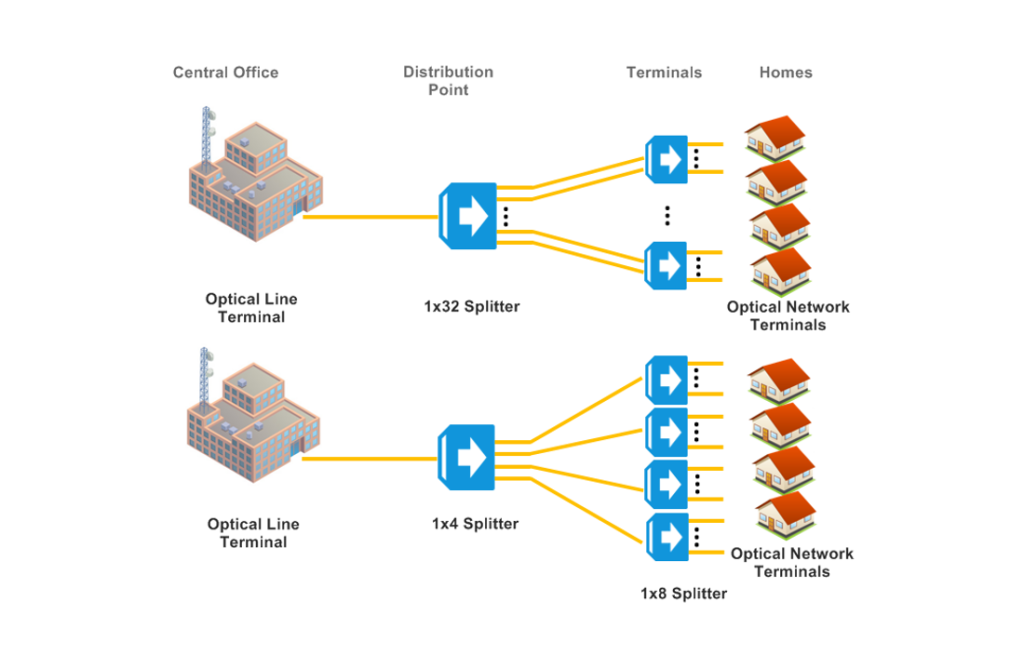

How does PLC Splitter Work in PON Network?

In Passive Optical Networks (PON), PLC splitters are widely installed between the PON Optical Line Terminal (OLT) and the Optical Network Terminal/Unit (ONT/ONU) served by the OLT. The single fiber link from the central office (CO) OLT is connected to the input of the splitter and is split into a given number of fibers leaving the splitter. The number of outputs in the PLC module determines the number of splits.

PLC splitter can be used in centralized PON architecture or distributed architecture. In the centralized PON architecture, the Central Office usually uses a 1×32 PLC splitter. In a distributed PON architecture, a 1×4 PLC splitter is first connected directly to the OLT port at the central office, and then each of the four fibers is routed to an external factory terminal/enclosure box equipped with a 1×8/1×4 PLC splitter.

Which Type of Splitter Should You Choose?

When it comes to choosing between FBT splitters and PLC splitters, there is no clear winner. The choice depends on several factors:

- Splitting Ratio: In system applications, it is defined as the output power of the output port of the splitter, which is related to the wavelength of the transmitted light.

- Insertion Loss: refers to the dB of each output relative to the input optical loss. Generally, the lower the insertion loss value, the better the performance of the splitter.

- Return Loss: also known as reflection loss, refers to the power loss of the returned or reflected optical signal due to a discontinuity in the optical fiber or transmission line. In general, the greater the return loss, the better.

- Isolation: It means that the optical splitter of one optical path isolates the optical signals of other optical paths.

In addition, uniformity, directivity, PDL polarization loss, and price are also key parameters affecting the performance of beam splitters.

Conclusion

The choice between the two types of splitters depends on several factors, such as the application, the required bandwidth, the available space, and the budget. As telecommunication networks continue to evolve, it is likely that the demand for PLC splitters will continue to increase, and they may eventually replace FBT splitters altogether.