Stock & Custom Fiber Termination Box Supplier

Bativ is your resource for single fiber to 72 cores fiber termination box, You will get strong support regardless OEM or ODM to better perform your projects.

Factory Price

14 Years Experience

Quality Assurance

* Free sample is available.

Featured Fiber Termination Boxes

Selected Fiber Termination Boxes for your FTTH & Outdoor Cablings, Easy and safe, No Overpaying, Fast Delivery.

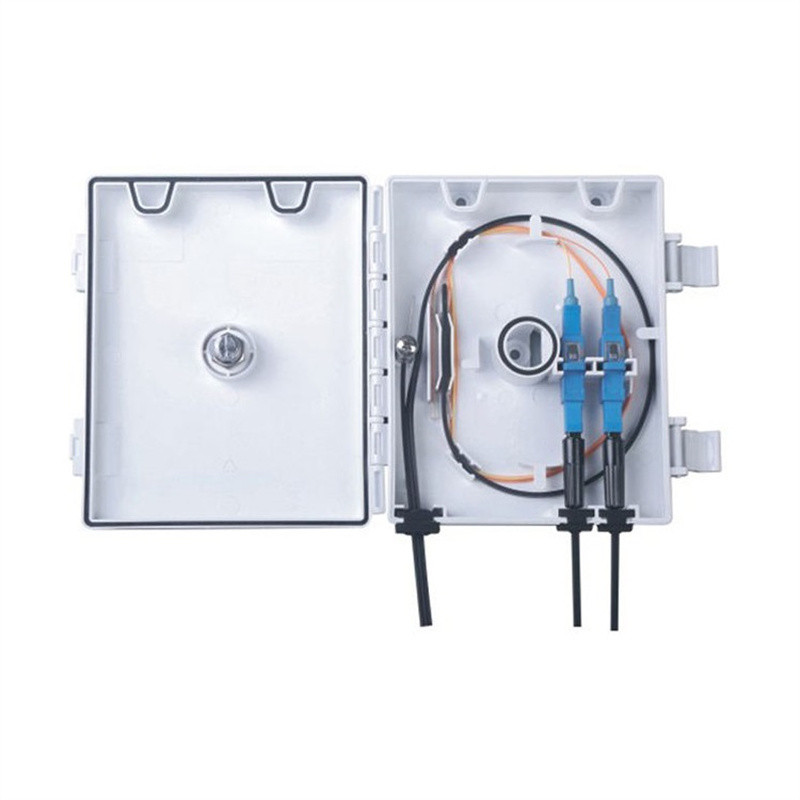

Single Fiber Fiber Termination Box

2 Ports Fiber Termination Box

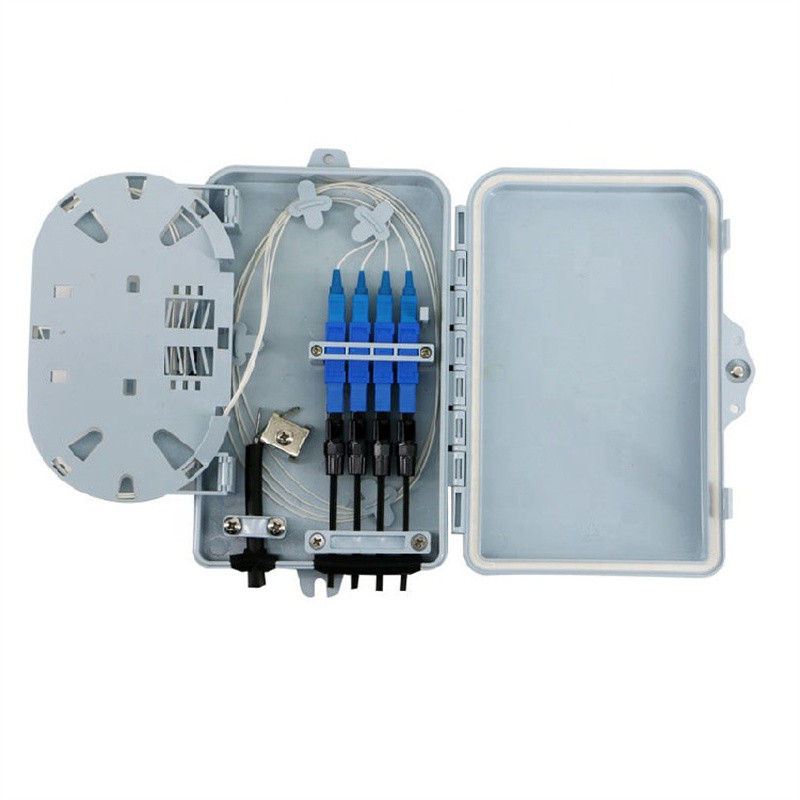

4 Ports Fiber Termination Box

6 Ports Fiber Termination Box

8 Ports Fiber Termination Box

12 Ports Fiber Termination Box

16 Ports Fiber Termination Box

24 Ports Fiber Termination Box

48 Ports Fiber Termination Box

Rack Mount Fiber Termination Box

Wall Mounted Fiber Termination Box

Fiber Termination Boxes Listings

Check Lastest Fiber Termination Boxes with price list, Then you can have a helpful benchmark for your procurements. For more assistance, You can contact us directly.

How to Choose Fiber Termination Box?

We are a fiber connectivity-based company that takes pride in our superior customer service, sending you the best Fiber Termination Boxes to your doorstep.

1

Fiber Capacity and Fiber Ports

That is how many fiber counts would be spliced or connected into this fiber termination box.

2

Installation Environment

Assess whether the termination box will be installed indoors, outdoors, in a wall-mount, rack-mount, or pole-mount configuration

3

Connector Types

Usually for FTTx Cabling, SC LC fiber connectivity is popular, But you should also understand it if you have special request.

4

Splicing or Connecting Options

To splice fiber pigtails with cable directly or connected them with fiber optic splitters.

5

Cost and Budget

Here in Bativ, We are supporting you with good quality fiber termination box at low cost, You can contact us any time to discuss with.

What we care about?

Premium Material

Understand your installation environments with premium ABS material

Useful Accessories

All fiber termination boxes should be coming with

LOGO Printed

You can put on your logo on any of the fiber optic termination box for branding in our markets

Smart Design

Good design makes your installation cost effective and easy to use

Fast Delivery

Usually there are some amount of them are in stock for your urgent need.

Robust Packing & Labeling

Make sure you can receive all freight as good as possible, and easy to check them at your warehouse any time.

What is more?

Custom or wholesale Fiber Optic Termination Boxes at low cost, 100% of good quality with 540 days warranty.

Your Fiber Optic Termination Boxes Supplier in China

Bativ is your one-stop supplier for all custom & urgent need fiber patch cord solutions. There are many options for your projects, such as 2 cores, 4 cores to 72 ports, Indoor or outdoor use, Rack mount and wall mount, With us, You not merely get more than a fiber termination box but a whole solution.

Packaging & Shipping

When we pack your fiber termination boxes, Each of them are in one inner carton and 20 to 40 inner carton into an outer carton. The most important thing is to keep your package safe.

FAQs

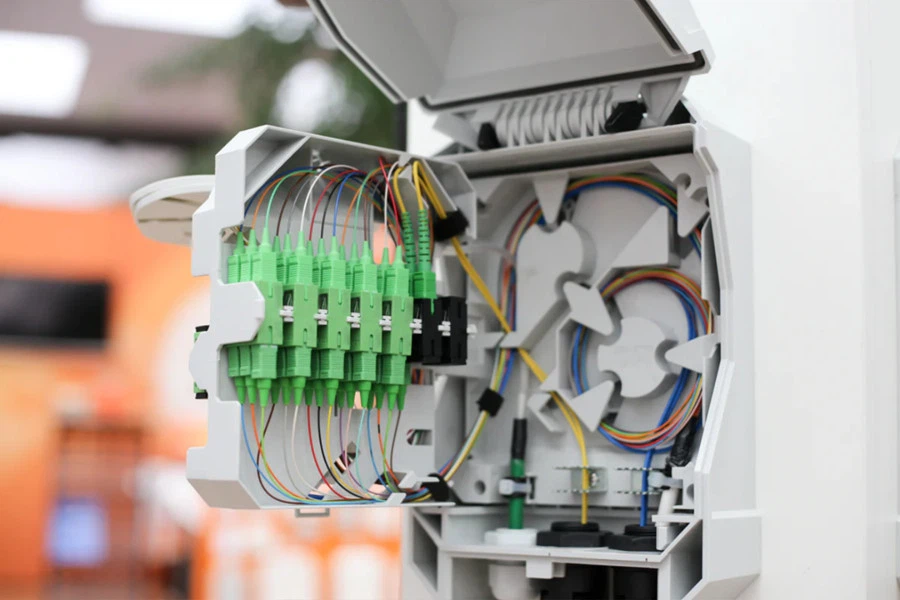

What is a fiber optic termination box ?

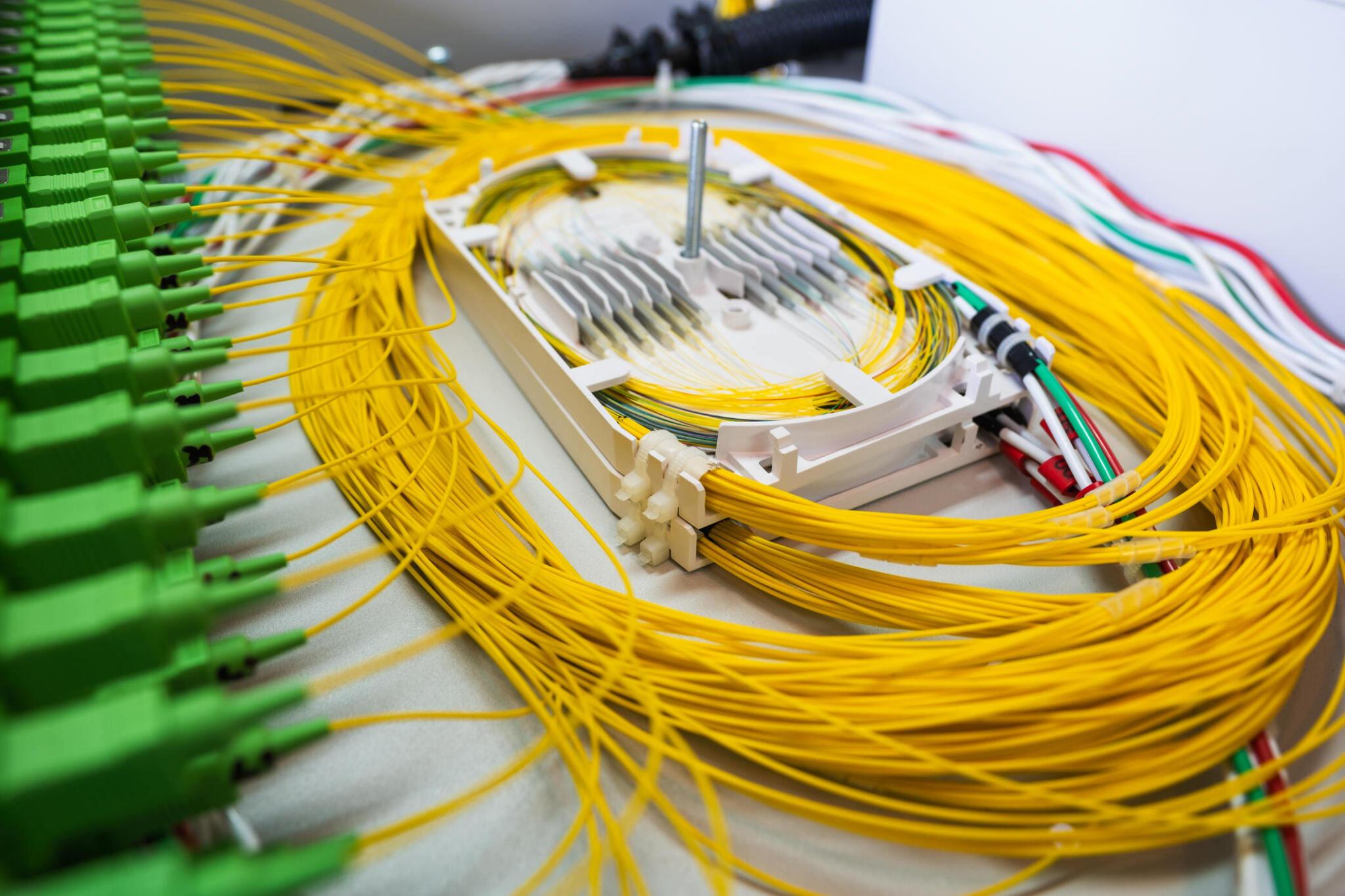

fiber termination box is an interface between the fiber cable from the line side and the pigtails to be passed to the fiber distribution frame. A fiber pigtail is a specific hardware connection used for cable termination.

Thus, a fiber termination box is used to terminate the optical fiber cables in the field and connect them to the pigtail by splicing. After an optical cable arrives at the user’s end, it is fixed in the terminal box. Then, the optical cable core and pigtail are welded in the terminal box.

What are the types of fiber optic termination box?

Optical fiber terminal boxes can be of many different types:

Based on Cable Connection Method

- Straight-through Terminal Box: This terminal box has a single external hole for the receiving line.

- Branched-type Terminal Box: This terminal box has several holes for the receiving line.

Based on the number of fibers fused

A terminal box can be divided into 2 in, 8 out, 4 in 24 out, 4 in 12 out, etc.

Based on the shell material

The terminal boxes can be plastic shell or metal shell optical fiber terminal boxes.

Based on the style

These boxes can be rack-drawer, wall-mounted, desktop-type, and other types.

Indoor Fiber Termination Box

The indoor fiber distribution terminal is a compact fiber box solution for installation requirements in small to mid-sized MDUs, multiple dwelling units, or multiple tenant units (MTU).

Outdoor Fiber Termination Box

Outdoor Fiber Distribution Terminals are used for installing fiber in small and medium-sized MDUs, or multi-dwelling units.

How to customize a fiber optic termination box?

Custom a fiber optic termination box is easy here with Bativ, You need to make clear your requirements, We will send you our draft for the custom fiber optic products, Take 2 ports fiber distribution box for example, We can make a 3D model for your reference until you are satisfied with it, Then we can get back to you with our best quote or sample for your quality evaluation.

How to use a fiber optic termination box?

Installation of the fiber termination box must be done under the supervision of a skilled technician or engineer. Here are the various stages in the installation of the FTB.

Mounting

The optical fiber termination box is mounted on the wall or on the 19 inches (483 mm) wide standard rack. The front panel should be easily accessible as the cable enters from the bottom.

Cable End Preparation

Any fiber cable’s end has to be prepared before starting the cable entry in the optical fiber termination box. The cable end preparation procedure is available from the supplier. It is crucial to protect the bare fibers at this stage. This is because they get exposed after following the cable end preparation.

Cable Entry

Once the cable ends are prepared, a rubber diaphragm at the box’s cable entry hole needs to be pierced. This is to be done before inserting the cable in the box, as this opening is blocked in new boxes.

Cable End Clamping

The fiber termination box has several plastic fiber guide posts mounted in it. The fiber in the sleeves or transport tube of the cable is routed through them. Through these guideposts, all the excess length of the cable is brought into the selected splice tray. Then, using a plastic clamping strap, it is clamped at the splice tray’s entry point.

Splicing

The most important part of the installation process is splicing the optical fiber from the cable to the pigtails. A splicing machine is used for this purpose. It is kept close to the termination box on a table.

A stainless steel wire mechanism is released from its spring catch to open a particular splice tray. A splicing machine is used to splice the pigtail fibers so that the fiber ends come out of the cable. They are then pushed to fit into the fused splice.

The process is carried on for all the splices to be stored in splice trays. These splice trays are then placed in a stack inside the termination box. The stainless steel wire closing mechanism is then closed with the box.

What is the MOQ and lead time for your custom fiber optic termination box?

It depends on the quantity you will order, Usually 1-3 days for 1000pcs, and 7-10 days for 1000-20000pcs. And 10-15 days for 20000 to 200,000pcs.

Can I get a FREE sample of fiber optic termination box?

Free sample is available any time, We believe it will be a good start between us when you tested our fiber optic termination box samples.

Send Inquiry Now

Bativ Services Always Go Extra Mile

OEM & ODM Available

Whether you want to have your logo on package or want to custom it differently, we can help you.

Lighting Fast Delivery

If you are no in need of special fiber optic products, just the finished product, The inventory will be of fast delivery.

Start With Low MOQ

If you want to wholesale fiber optic products, we support a minimum order quantity of 1 pcs for the first order.

Trusted by Big brands since 2010